You want to be more productive, to do more things quickly, but with better quality of work done. Your own productivity will be based on the workplace, where the job is usually done. So, use 5S and make your workplace more productive.

Do you find yourself in a position where you lose time finding a physical item around you in your office? Do you find yourself in a position to spend too much time trying to find a document on your computer?

If you answer yes, then you want to reorganize your working environment.

In this post, I want to discuss how to help you organize stuff in your workplace using the 5S methodology.

Toyota Production System as a Foundation of 5S

Lean management, or lean manufacturing (some also call it lean production), traces its historical roots in Japan, specifically in Toyota Motor Company. It is also known as the Toyota Production System.

Most authors believe this philosophy came between the 60s and 70s of the last century, when Toyota’s successes were noticed. But I still think that the foundations of this philosophy are somewhere in 1937 and were started by the man who is the founder of Toyota, Kiichiro Toyoda.

At the very beginning of its operation, Toyota had competitors such as Ford and General Motors. Kiichiro Toyoda has set the goal to offer a car for the same or lower price than competitors but with better quality. That’s why he started with how much the customer was willing to pay, and based on that, he made calculations for the development and production processes. So, this is the main origin of something we know today as lean manufacturing.

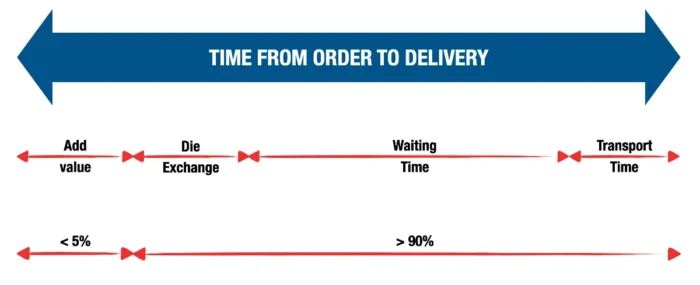

One of the basic principles of lean manufacturing is reducing the time from order to delivery of finished products. And one of the non-value-added times is searching and finding the right tools for the production process. So, the 5S methodology minimizes waste related to this non-value-adding time.

What is 5S?

Simply put, 5S is good housekeeping at another level as a first step in improving productivity. 5S is part of developing a visual workplace.

When you feel better, when you can find needed things easily, or when you spend time looking for them?

5S is a powerful system of organization named after five Japanese terms for each step that must be conducted. Hiroyuki Hirano developed The method in Japan, and it is primarily used in lean manufacturing, or the Toyota Production System.

However, the main objective of the 5S tool is to educate you and your team members and encourage a mindset that supports important employee habits. These habits will allow employees to maintain the work environment orderly with little effort.

The 5S methodology brings a new awareness and respect for proper organization and cleaning into the work environment.

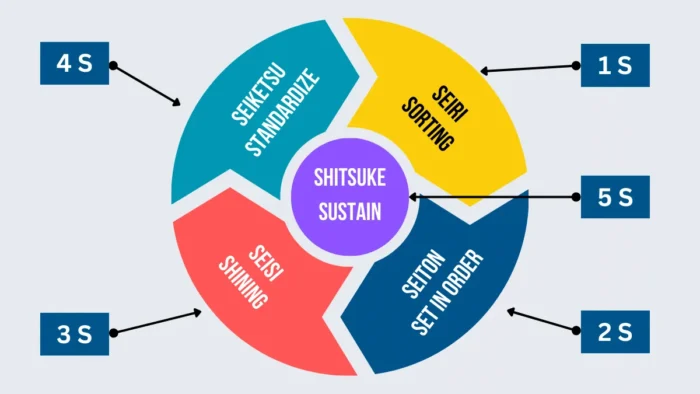

The name “5S” comes from a list of five Japanese words, starting with the letter “S.”

- Seiri – Sorting.

- Seiton – Set everything in order.

- Seisi – Shining or cleaning.

- Seiketsu – Standardize.

- Shitsuke – Sustain.

Why You Need to Implement 5S Methodology

You can not automate any workplace if there is disorganization in place. The 5S methodology is something that can help you implement strong organizational principles everywhere inside your organization. Especially when it comes to tools or equipment used.

So, first, I would like to talk about some benefits you can achieve with 5S:

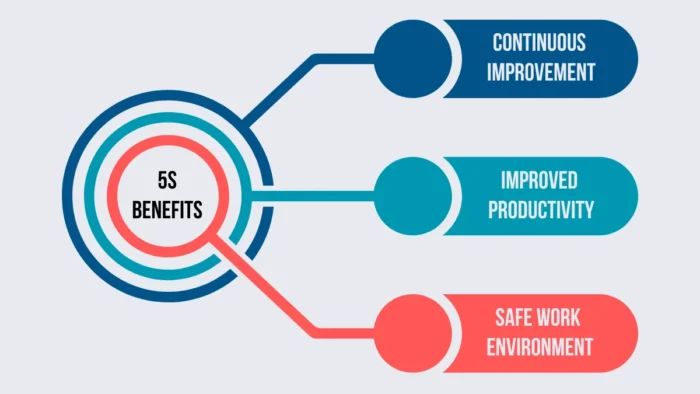

5S is Continuous Improvement Itself and Bring New Improvements?

Implementing the 5S methodology will help your company to start with a continuous improvement process. The methodology consists of five continuous improvement steps. These steps will open new practices for more improvements after the implementation.

Remember, 5S methodology is the cornerstone for continuous improvement.

Improved Productivity

Suppose you are dissatisfied with your operational efficiency. In that case, implementing 5S is the first thing you must do to find all the reasons behind low efficiency and improve your company’s productivity.

Think about a messy workplace, and you want to find out why this workplace is not productive enough. If you start with improvements, you will still have so much junk there. So, it will cover improvement possibilities that are invisible to you. So, without implementing 5S, before you focus on other improving tools, your efforts will not bring desired results regarding productivity.

For example, equipment waste (idle time) is often related to tools and part searches, which are eliminated thanks to 5S. Eliminating waste means eliminating idle time and, in such a way, increasing productivity.

Another example related to productivity and 5S is cleaning, which can increase equipment availability by reducing the time required for maintenance tasks.

Safe Work Environment

5S methodology will require maintaining a clean work environment that minimizes sliding or falling risks. Also, a properly organized workplace implementing 5S principles will remove clutter and its associated safety risks.

Areas Where You Can Implement 5S and Achieve Continuous Improvement

Although the 5S methodology describes numerous examples of improvement in manufacturing facilities, it is not limited only to them. You can do the same for offices, warehouses, common areas, etc. Whether we talk about office space or the production floor doesn’t matter. The workplace organization is necessary if you want to achieve success.

So, here are some areas where you can start implementing 5S:

- Production floor,

- Storages,

- Office, and

- Digital Files

Definition of Terms We Will Use for 5S Methodology

Let’s first talk and make a clear distinction between some key terms we will in 5S methodology implementation:

Necessary VS Unnecessary Items

These two terms we will use continuously through the implementation of the 5S methodology because they are a starting point not only for 5S but for any other process improvement program you want to implement.

Necessary items are all things like tools, equipment, materials, etc., that some specific workplaces will require for conducting everyday tasks. I will give you an analogy with your smartphone. Look at your phone and check how many applications you have. Probably many, like email clients, social media apps, games, to-do list apps, etc. When I look now inside my iPhone, the first thing I’ve seen is that even I have changed my email client from Airmail to Spark, still I have not deleted the Airmail app. It is still there.

Now, look at the report like the “Screen Time” report. Inside my report, I have six apps used every day in the last six days, even though I have hundreds of apps installed. So, these six apps, Spark email, Calendar, Safari, Facebook, X, and Calendar, according to this report, are necessary items; even though there is a question of whether social media apps are necessary, we are not using phones only for work, but also for pleasure.

On the other hand, we have unnecessary items, including waste, that some specific workflow will not require to be used daily, or they do not add value to our work. So, the question is, do we really need them? We know that we must eliminate waste, but what about other things?

It doesn’t mean I must delete all the rest of the apps. Why? My report shows me for the last week, but I also have some apps that are not used frequently, but sometimes they add value to my work, like scanner apps. Still, even I have a folder for Scanners apps, I have three applications and use only one. So, the two applications are unneeded items inside my iPhone, and I am deleting them now.

Visual Workplace

Visual workplace in 5S means that we must incorporate visual thinking so that when we only look with our eyes, we will know where and where we can not, where a specific tool or equipment is, etc.

The 5S methodology is something that will require us, when implemented correctly, to use a visual management approach for different areas inside the work environment that will ensure self-explaining, self-ordering and self-improving approaches. Remember that visual management and 5S are closely integrated because 5S maintains workplace organization visually, using visual cues such as shadow boards and labeled containers.

Process Improvement and 5S

Finally, it is important not to set very demanding goals in a 5S project. If the intention is to develop many improvements, and some of them fail, the whole project can be seen as a failure. For example, the 5S methodology may intend to improve worker results or methods. However, this represents a process improvement and should be viewed as an independent project. As a result, it should be separated from the 5S implementation process. That is to say, it should not appear in the 5S panel or be discussed in the meetings.

How Can You Use 5S to Increase Productivity?

As I have already discussed, the 5S is a process using five stages or steps that must be implemented in the workplace.

Let’s go into the step-by-step process of the 5S methodology.

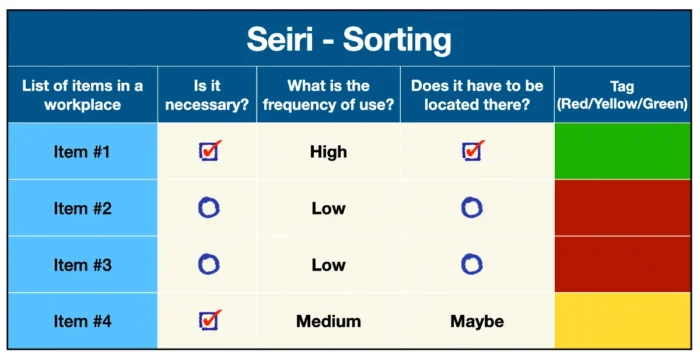

1. Seiri – Sorting

First things need to be as first. You don’t want to improve something unnecessary in your daily working routine. So, first, 5S requires you to start with the Seiri and sort everything around you in your workplace.

Sorting means removing all unneeded items from the workplace that no longer add value to your work. You would be surprised to find out that you need very few items as necessary to do the work. Everything else should disappear.

Use the following question to help you start with the sorting step as a part of 5S:

- What do I have around me in my workplace?

- Do I really need this?

- What items do I need to eliminate?

Why Sorting is Important in 5S?

Sorting is important because it will improve safety in the workplace and the workflow by removing items that can distract you when you work, which will definitely increase productivity.

The necessary items and tools required for the job can easily become hidden, and in such a way, your employees start conducting nonvalue-added activities. After successfully sorting out and eliminating all unnecessary items, the items inside your workplace can be less than 30%, and sometimes I have achieved more than 50% with clients, depending on the state in which it is currently. So, with the first S from the 5S methodology, you want to discover what you must eliminate and eliminate it.

Tools You Can Use for Sorting

Regarding sorting as a part of the 5S methodology, the red-tagging tool is one of the most important.

This is a simple and visual method to help you and your team members to separate necessary from unnecessary things. With this tool, all of you must assign a red tag to the items that are not used or whose use is unlikely.

So, put red tags on each thing that will not be used in the next month, although at first, they will be placed only on things that are completely unnecessary.

For example, you can use a second color, yellow, for a tag that means “may be useful.” But remember, when implementing the 5S, use yellow tags only for the remaining items after you eliminate everything with the red tags.

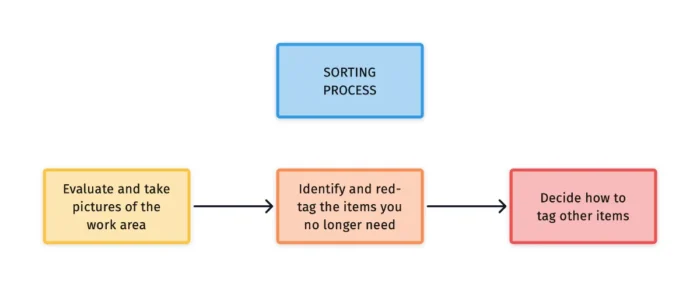

How to Conduct the Sorting Process?

As you already know, with sorting, we first want to eliminate and reduce waste with other trivial things inside our workplace. Generally, the process you must conduct for this step has three steps:

- Evaluate and take pictures of the work area.

- Identify and red-tag the items you no longer need.

- Decide how to tag other items.

- Those that are used frequently.

- Those that probably will be used.

- Those that never will be used.

The sorting message is very strong: You must eliminate unnecessary things in a specific workplace!

Elements belonging to one of the last two categories should be removed from the work area. It is logical for those that never will be used, but also those that probably will be used don’t need to be on a workbench or desk but can be stored in a special area for such a thing.

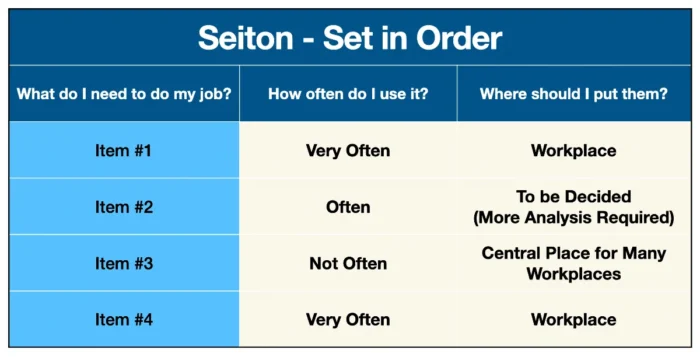

2. Seiton – Set everything in order

You can start making the order when you eliminate everything you don’t need and know how important a specific item is (Seiton).

The second step of 5S means you must locate a place for everything, and everything should be in its own place, ensuring easy availability when you need specific items.

Answer the following questions because they will help you in this phase:

- How important is a specific item for my work?

- How often do I use each item daily, weekly, and monthly?

- Is the item in the right place?

- What do I need to do when I need a specific item?

- Is it the movement that I make when I need a specific item optimal?

- Is the place where each item is placed in the right place for my working routine?

- Where will each item be placed?

- How will the places be marked?

Many experts say that you must eliminate that item if you are in doubt or have responded with maybe. But, as you can see from the questions above when it comes to implementing sorting as a part of the 5S methodology, I don’t want to remove items I am unsure about. According to my experience with clients, it is best to prioritize according to the frequency of use.

Why is “Set in Order” Important in 5S?

This step in the 5S methodology is very important because it enables every item to have a specific place to be easily found whenever you need it.

When you implement this step of 5S, you will start reducing waste from excess motion because everything you need more frequently will be in place of your hands, and everything not used frequently will have a special place to find it easier.

Also, set in order will free up space that can be used better for your company.

Tools You Can Use for “Set in Order”

You can place signs in various areas of the company, but ensure that they will be used everywhere where they can facilitate some specific searching tasks.

For example, when an employee needs to get up to find a specific item or tool required for his job, with the sign, he will know the correct location of what he needs. In such a way, you will get a productive workplace because there will not be a need for unnecessary motion or losing time to find something important for the job.

With this helpful tool, you can easily ensure it is easy to see if an element is placed correctly.

Another tool that is usually used in 5S methodology is a painting or floor tape that focuses primarily on floors and walls to separate walking areas from working areas or hazardous materials from nonhazardous materials.

For example, areas of high risk should be identified with tiger marks (yellow and black), or you can use floor marking tape to indicate something related to safety. Floor marking tape is also one of the visual tools that will translate important information for employees and visitors inside your company.

Also, you can use shadow boards to organize different tools and equipment. The shadow board is a visual method that has a picture of the tool or equipment and, in such a way, makes it easy to identify if something is missing.

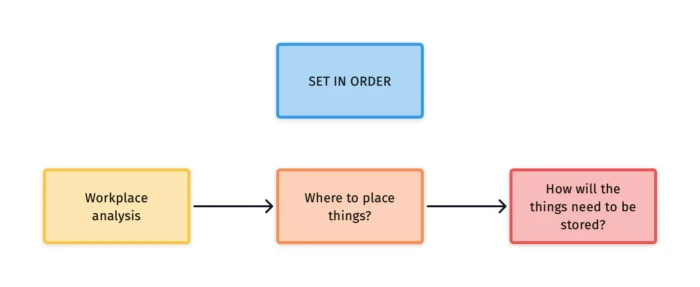

How to Conduct Set in Order Process?

To conduct set in the order step as a part of implementing the 5S methodology, you must go through the following three steps:

- Workplace analysis. The first step to conducting a set-in-order process is to analyze each workplace and find out what tools and supplies are needed for each workplace to conduct the work most efficiently. Usually, I give the sheet to my client’s employees that everyone will need to fill.

- Where to place things? After analysis, you must decide where to place each remaining item. For example, if a specific tool is frequently used, it can be on a working bench or desk, always available for the employee. In this way, you will improve the efficiency of each of your employees.

- How will the things need to be stored? When you know where the place will be for each item, you must decide how it will be stored and what you will need as an organizational system when it comes to storing. You must ensure that all items are easily accessible and can also be easily retrieved from their place.

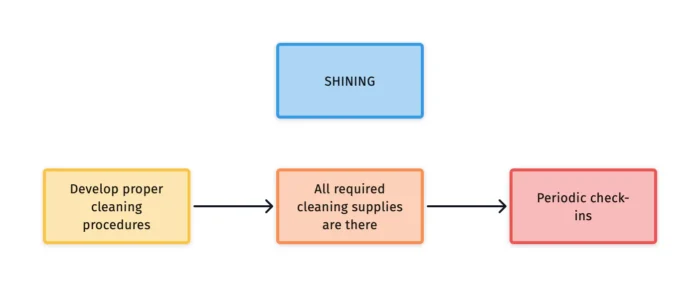

3. Seisi – Shining or cleaning

Now, when you eliminate everything that you don’t need, everything has its own place, and everything is in its own place, you have a much better workplace around you. Next, you will need a cleaning routine (Seisi or Shining). A clean work environment is much more productive than a disorganized and dirty workplace.

Shine is the third step that attempts to implement cleanliness in your workspace. In other words, maintain the workplace clean at all times. It is important to mention that this should be a constant attitude and a daily task.

At the end of each workday, you need to clean your work so that everything will be in its own place, ready for your use tomorrow.

The key point is that cleaning and restoring should be part of your daily work routine. If you use this phrase only occasionally, your workplace will soon become messy, disorganized, and dirty again.

Why Shining is Important in 5S?

Keeping the workplace clean and organized will give your employees a sense of satisfaction, and you will find that they will want to keep things that way.

Also, this step is not only good for impression, but it helps to prevent accidents and possible injuries. Wet, dirty floors are a safety hazard for all employees walking through your company, so they should always be kept clean.

When it comes to tools, they should always be kept clean and maintained regularly and in such a way as to ensure proper use and longevity.

Tools You Can Use for Shining

Cleaning tools will be used depending on the specific workplace and the level of dirtiness after conducting the specific job. For example, if the company is from the manufacturing industry and the specific job will generate a large volume of waste, you will need an appropriate tool for eliminating waste.

When it comes to the office, you can probably use specific cleaning services that will eliminate dust, conduct vacuum cleaning, etc. However, shining as a part of the 5S methodology includes a clean office desk, computer, etc. For example, your keyboard can become dirty after some period of time, and you will need to clean it.

How Can You Conduct the Shining Process as a Part of 5S?

The question is how to maintain cleanliness as a part of 5S methodology always across your company.

Conducting specific work processes, especially in the manufacturing industry, can often dirty a workplace. So, at the end of each shift, you want to ensure that the workplace is clean and ready for the next shift.

To ensure that you will incorporate a shining process inside each workplace, you can:

- Develop proper cleaning procedures for each workplace inside your company. Proper cleaning procedures mean that every workplace will have a procedure and be responsible for cleaning after the job is done.

- Ensure that all required cleaning supplies are always at the disposal of each of your team members. If there is a need to use specific cleaning supplies, they will always be there for them.

- Conduct periodic check-ins to ensure that your cleaning procedures are implemented regularly. This is an important part of 5S if you want to ensure that cleaning becomes a habit.

4. Seiketsu – Standardize or Visual Control

When you know what you need, where it needs to be placed, and how to keep things organized and clean, you need to standardize those work practices (Seiketsu as a part of 5S).

This step from 5S is not a one-time show that you will implement and forget. You must standardize practices from the first three “S” into your company’s daily routine. In such a way, you can easily and quickly improve your workplace to be more productive.

In many cases, you can detect irregularities visually, and the action to correct them should be instantaneous. Because of that, this step is also known as visual control.

Why Standardization is Important in 5S?

If you want to transform the previous three steps into a habit, assigning responsibility to the employees is necessary. In other words, it is necessary to integrate all tasks related to 5S implementation into the employee’s regular work (daily routine).

Once you standardize the work, the process can be modified continually to make it even more efficient. With standards in place, your company can easily conduct a continuous improvement process.

Tools You Can Use for Standardization

One tool that can be used for standardization is checklists. So, when you implement the first three steps of 5S, you can build checklists for implementation and audit for each workplace that will give your employees step-by-step instructions on keeping their workplace organized.

Also, as a standardization tool, you can use images of the right organized workplace, so employees can always compare the image with the actual situation.

How Can You Conduct Standardization Step as a Part of 5S?

To ensure standardization of the 5S program, you must develop written standards to monitor its progress.

This is the process of documenting and standardizing all tasks through standard procedures that will be used at all times, on all shifts, and by all employees.

In such a way, your employees will know exactly what to do, when to do it, and how long to do it. So this will reduce variability within your processes and improve productivity.

5. Shitsuke – Sustain

Once when the first four S are established and implemented as something normal in your company’s daily working routine, you will need to check and review the process to find better ways to organize stuff around you (Shitsuke from 5S). Find what’s the best time to review your standard procedures to maintain and improve your workplace.

Why Sustain is Important in 5S?

As you can see, implementing 5S as a lean manufacturing tool will require some changes involving all employees. And you know that change is never easy, and achieving the sustainability of the 5S program is the most difficult challenge. People naturally always resist change, so many companies complete the first four Ss only to have a mess again after some period of time.

An important thing you must know is that if the workplace returns to its initial state of “disorganization’” after implementing the 5S methodology, it will be more difficult to implement the same thing again. So, you must ensure that everything is done properly from the start.

Tools You Can Use for Sustain Step

To achieve sustainability in this new work organization, you must use some promotional tools in the project that will motivate your staff.

There are a great number of promotional tools. Some of them are listed below:

- Slogans. Slogan posters contain short sayings.

- 5S newsletters. Newsletters are weekly or monthly reports that present ideas, improvements, and pictures.

- 5S competition. You can also implement competitions among different sectors over some period of time, called 5S months.

- 5S seminars. Also, you can conduct periodic seminars about the importance of 5S.

- 5S pocket manuals. You can publish small manuals illustrating ideas to implement the 5S methodology in the workspace and distribute them to all employees. This can help you overcome resistance to improvements among different departments.

How Can You Conduct Sustain Step as a Part of 5S?

First, you must develop a tracking system for the 5S program. You want to know what your team members have achieved and encourage them to continue giving their best for better results.

Also, you can implement an easy scoring system for achievements with a tracking system in place. You can offer incentives for the highest scores based on the scores achieved.

6. Incorporating Safety into Lean 5S

Some people talk about the sixth S as an extension of the 5S methodology. This sixth S is related to safety, or establishing and practicing safety procedures at each workplace.

But, I think that if the workspace is properly organized (first two Ss) and cleaned (third S) and utilizes helpful safety visual cues (fourth S), a separate safety step is not necessary.

Before You Start Implementing 5S Methodology

Before starting with a 5S implementation, there is an initial step that is basic to the success of this methodology. Here are some things you must consider:

Prepare initial training material

Start with the initial training materials to explain to all the employees the importance of the 5S methodology and the basic knowledge they should have about it.

Remember that adequate training programs concerning the reasoning behind and the scope of the 5S implementation are considered the most important step.

Start with the pilot project in one area

To show the importance of implementing a 5S project and motivate your staff members, start small as a pilot project in a specific area where you can achieve spectacular results in a short period of time.

Once the results of implementing the 5S methodology in the pilot area are known, you can extend the process to other areas.

Design implementation plan

As in everything else, the 5S methodology will require a solid implementation plan to ensure performing tasks important to achieve success. So, when you are developing your plan, include:

- all important and basic steps that will need to be taken,

- define all production processes where you will implement 5S and that are most important for your company,

- define the decision-making process,

- locate possible storage locations,

- list all necessary supplies you will need and

- assign responsibility for each area where you will implement 5S.

Implement 5S methodology

Now is the right time to put the 5S process into practice. Start with the implementation of your plan. After completing each step, ensure that your team members will share their experiences so all of them can improve based on each other’s experience.

5S Success Story

I have experienced the implementation of the 5S methodology in dozens of companies. One great example is a service-based company that conducts services for different equipment for different clients.

The 5S process we implemented with the owner was similar to what I described above and used the same tools and templates. One important additional tool that was not mentioned above and we have used was cameras that record each movement in each workplace on the service floor. So, here I want to talk about the achievements.

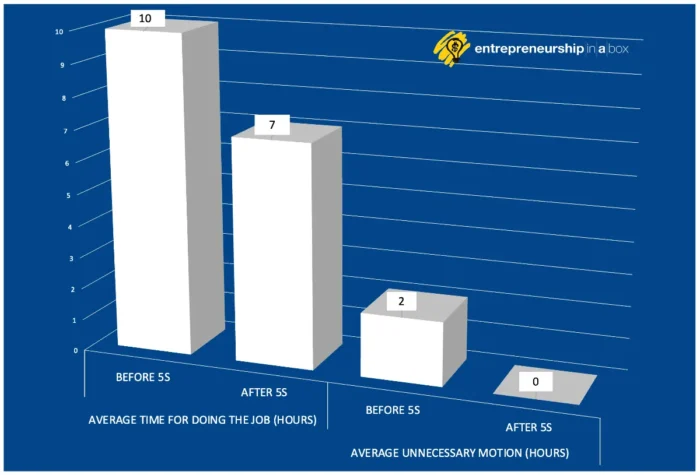

First, I have shared the Excel templates with tables that each service worker was required to complete, and in such a way, we have collected what they have on their workbench and how frequently they use all those things. Next, with the help of cameras, we analyzed how each employee spent their time doing the work. These were great data for analysis, and here are before and after 5S states.

Before the implementation of 5S, the average time for doing service for one piece of equipment was around 10 hours. According to the recorded period from cameras, we have found that each employee wastes around 2 hours on average to find the necessary tools and unnecessary motion. When we reorganize each workplace, remove unnecessary things from the workbench, and organize necessary things according to the frequency of use, we reduce these two hours to zero. Also, we get an additional hour after changing the layout inside the workshop. In this way, we improve efficiency, productivity, and customer satisfaction because they will quickly get their equipment services.

So, 5S is really a great tool that you should give a try.