Wherever lasers are used within manufacturing processes heat is generated. Chillers are essential in removing the excess heat that can potentially damage equipment surrounding the laser, the laser tube. It can also compromise the accuracy of the laser, its quality, and the wavelength that it operates at. Process cooling systems for lasers work to extend the equipment’s lifespan by preventing overheating.

Maintaining a consistent temperature ensures the efficient running of a laser and preserves its lifespan.

Laser applications

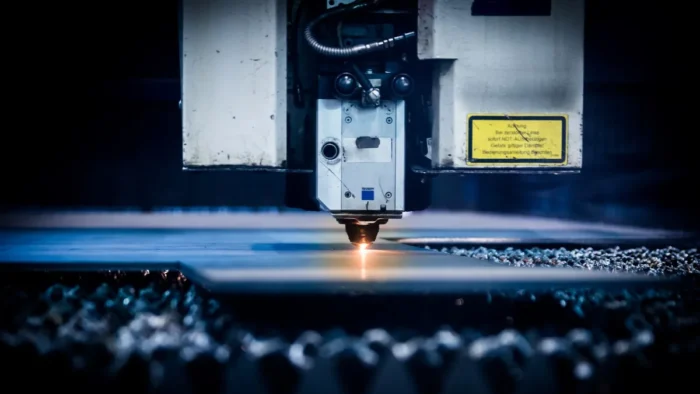

Lasers are currently used within industry for a variety of different processes including:

- Welding – Powerful fiber lasers are used to weld two pieces of metal together to form a strong bond between them.

- Ablation – Lasers are used to remove the top layer of a material in order to reveal the surface that layers beneath.

- Engraving – Lasers are used to leave a deep level engraving into a material, such as metal or plastic.

- Cutting – Lasers are used to cut through a range of different materials rather than the traditional cutting blades. Using a laser means there is no need to purchase replacement cutting blades, which can be expensive. This also means that the machine never needs any downtime.

- Drilling – Lasers are used to replace the standard tools for drilling and instead focus a fiber laser that is highly powerful onto the materials to produce dents or dill holes.

- Cleaning – Lasers are used to melt the surface layer to reveal those underneath. They can also be used to get rid of the entire top level of a surface or object.

Most modern products that are aimed at consumers will have had some interaction with a laser.

What industries use lasers?

The user of lasers is prevalent in numerous industries including:

Automobiles

Lasers have been used in the building of cars since the 1980s. The production of all modern motor vehicles includes the use of lasers throughout various different parts. They are used to cut cloth for airbags, welding the body, marking tyres, and lining doors.

Semiconductors

Lasers are used to cut materials cleanly and rapidly during the manufacture of semiconductors. They are able to cut the irregular shapes that are required to an excellent level of precision. Printing onto circuit boards and marking silicon, polymers, and metals are other applications lasers are used for within this industry. Lasers are able to inscribe as many as 1,000 letters each second.

Jewelry

Laser engraving machines are widely used in the jewelry business as they provide a high-level of precision that is difficult to achieve with traditional engraving techniques. These machines can be used to engrave great designs on jewelry pieces, even ones with complex patterns or curvatures. Furthermore, laser engraving is much faster than hand-engraving which makes it perfect for high volume orders. Also, they produce a much more detailed and precise look than hand-engraved items, making it an ideal choice for businesses who want to create beautiful, high quality jewelry pieces.

Paint stripping

Mobile lasers are used in the removal of contaminants and paint from large objects such as ships and aircrafts. The lasers used are focused so that the paint or contaminant fully absorbs it, giving a fully clean and stripped surface. They leave little residue as the laser only makes a slight impact on whatever the subsurface is.

Packaging

Marking, perforating and scribing are some of the ways that lasers are used within this industry. Other more precise uses include producing easy to open packages via focusing the laser to weaken specific layers within the packaging. They are also used to puncture tiny holes in fruit and vegetable bags that allow the produce to breathe and thus last longer. Strong lasers are often used to remove tiny amounts of material from packaging surfaces, as well as modifying them with a high level of accuracy and speed.

Quality control

The quality of ball bearings is established by shining a laser onto them. The amount of light that is reflected back helps to determine how round they are and thus if they meet the quality requirements of the manufacturer.

Coding

Laser marking is largely used in the manufacture of beverages and food stuffs. They work by marking barcodes and other codes, and symbols and logos onto metals, paper, plastic and glass. Using lasers for this speeds up production and means the markings are better prepared to withstand extremes of humidity and temperature.

Different types of lasers

Lasers come in several different mediums, including gas, excimer, solid state, fiber, YAG, dye, semi conductor / diode, and disc. Not only do these have different applications within industry but the amount of power and heat they put out is different, as well as their wavelength. This means that they all have different cooling requirements.

The amount of power a laser puts out ranges from Milliwatt through to Petawatt. Those lasers that have a low power output, such as the ones found in disc readers and laser pointers come with a cooling system built in, in order for them to stop overheating and damaging any surrounding components. High power output lasers produced masses of heat, which requires removal. The best way to remove any heat generated is by the use of a laser cooling solution.

Laser cooling solutions

The greater amount of power output that the laser produces, the more heat that is generated. Lower powered lasers generally come with fans fitted that air cool the equipment. However, higher powered lasers, such as the North Slope laser chiller, generate much more heat and so need more effective cooling systems. Depending on the laser’s power output, it either requires a fluid cooling system with either a glycol/water mixture or deionized water.

What are the benefits of a laser cooling solution?

There are several benefits of utilizing a laser cooling solution. These include:

- Reducing thermal stress – Reducing the temperatures during industrial / manufacturing processes works to protect equipment and materials, increase the laser’s lifespan and reduce the need for maintenance.

- Maintaining wavelengths – Excessive heat build up within a laser increases its wavelength and thus compromises its performance.

- Maintaining beam quality – A strong focusing of the laser beam is needed for applications such as cutting, printing, engraving, and drilling. Any fluctuations in the beam can be both destructive and dangerous.

- Maintaining efficiency – A laser has numerous set specifications that enable it to perform accurately. If it becomes overheated it can become impress and dangerous, making it difficult to use the laser in a stable manner.

An efficient and robust laser cooling solution will help to mitigate the issues raised from laser use and help to keep industrial and manufacturing operations perform smoothly.