The creation of anything is not as easy as we think that. When we have some creative things, we should pay attention to its creation and designing that took a long time and more management. As technology is faster and Up To Dates. When we are moving from design to parts creation, the most important is choosing the right way to create the parts. For this purpose, many ways are introducing with the time.

Here we are discussing the two best methods that are commonly used and consider the best as well. When you go through these method details, you will surely judge what the best method for the molding is.

CNC Machining

Computer numerical control, commonly called the CNC, is an automated control machining tool that uses the preprogrammed computer software to manage the factory tools. It is a 3D printer means of a computer. This process is started from the block of precise material and allows different materials to use with few limitations and precautions. CNC is commonly used to removes the specific amount of material layers from the raw product to get the final product.

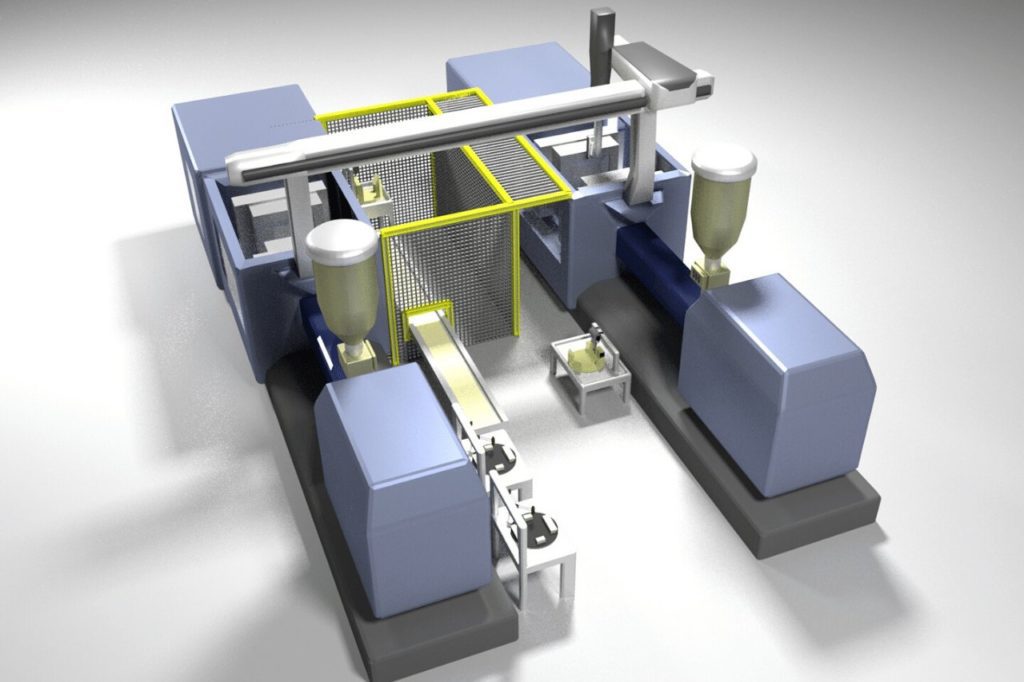

Injection Molding

This is another manufacturing process that is based on the injection. In this method, the plastic mold is injected by the nozzle through a cavity. This procedure is done by melting the materials and forced them into the mold with maximum pressure. The molded tools are mounted with movable platens. When the tools are dry, the ejector pins are used to open the platens. With the repetition of the injection molding procedure, many tools and parts are prepared within the time. Injection molding is performed for glasses, metals, elastomers, and polymers.

Which Procedure is Best- Machining or Molding?

If we summarize both procedures for product development, then we know that CNC machining is used for prototyping, large complex volume, precise tolerance, and small in quantity. At the same time, the injection molding is fit for the large quantity, where the skin textured and appearance of the tool is matter allot.

Here are some attributes from which you can easily judge both procedures. From these features, you will also choose which is the best for your product.

Related:

Material

CNC machining comes with a wide range of material, from plastic to wood. For proper design, it is imperative to select either you want high-quality plastic and lower quality. In injection molding, the material selection is limited. The reason is that molding is involved in meeting original material into the liquid form.

Speed

CNC machining is faster than the molding one of you want more production in a short time, and you will choose the CNC. Machining easily gives ten parts in a week. At the same time, injection molding requires some time to mold the material. CNC works in weeks, and the molding works in a month. Molding gives 50,000 parts in 3-4 months. So you can easily judge the speed.

Design

The product design is matter allot that comes from these procedures. So, if you have the mind to get the less cost-effective product, prefer the CNC machining. The upper features are made with the use of machining. The injection molding is cost-effective and takes more time for product development. The molding gives in-depth features of the product.

Cost

Undoubtedly, the cost is an important factor that should keep n mind while choosing machining and molding. From companies, you will quickly get the depth information about the cost. However, the cost is related to production volume. CNC machining does not change the product cost as quantity goes up as compared to the injection molding drops significantly when the product is molded well. In short, words when we pick the procedure through cost over volume, then injection molding is best.