Metal fabrication is one of the most important industries out there, as it ties into other major industries, and without it, all the other industries that rely on it would likely collapse.

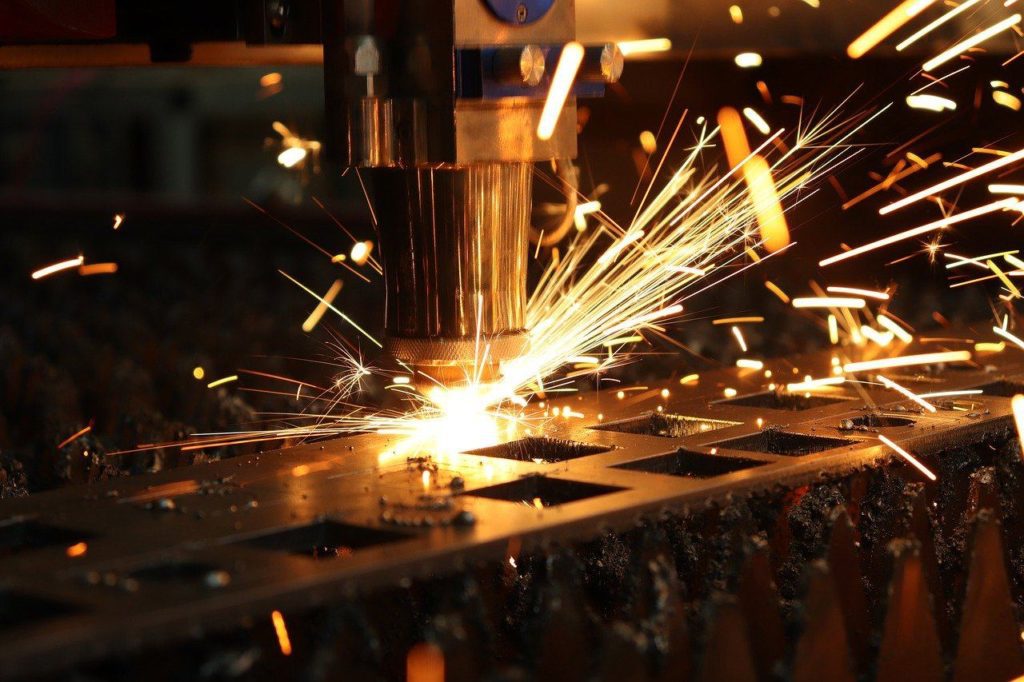

Metal fabrication involves building structures and machines from raw metal materials, and so it involves many processes such as welding, cutting, machining, burning, forming, and the assembly required to come up with the final product, like metal stamping.

Here we dig a little deeper into what it is all about.

Metal Fabrication Touches Everything

Metal fabrication projects touch almost every aspect of our lives. If you live in an apartment, it likely has metal railings for safety reasons. The building itself has a steel skeleton that was built by metal fabricators through different processes. Hardware, spring, wire, nut, and bolt manufacturing industries all depend on metal fabrication processes.

Industry Characteristics

The metal fabrication industry has some specific characteristics that differentiate it from or aligns it with other industries. One of these is that the metal fabrication industry relies on economic growth to survive and grow. As the economy grows, the demand for metal products grows with it. This is because a growing economy leads to more disposable income in the hands of the populace. As this happens, people are likely to purchase more boats, cars, and build more houses.

Also, as the population grows, there is an increased demand for new houses which means construction picks up and so does the metal fabrication industry. A growing population also leads to an increase in the demand for agricultural produce, which leads to a higher demand for commercial and agricultural machinery.

✋ Warning

Steer clear of metal sourcing missteps! ⚠️ Learn the pitfalls to avoid for your commercial enterprise! 🏢

To keep growing, the metal fabrication industry also makes adjustments such as taking on fewer larger projects so as to maintain a consistent sales volume which helps players in the industry maintain yearly profits.

Contract metal fabricators like TFG USA understand that to move forward, the metal fabrication industry must continue to innovate and diversify as they follow successful templates from previous years. This diversification and innovation can help mitigate the effects of the cyclical nature of the industry.

Remember, the metal fabrication industry depends on other industries such as construction, energy, and aerospace. This means that if these industries are affected, the metal fabrication industry is too, but if there are new innovations introduced, these effects would not be too severe to the metal fabrication industry. This is because these other industries would have to incorporate the new innovations which would maintain the demand for products produced by the metal fabrication industry.

📖 More similar articles

Maintaining Profitability

Metal fabrication shops understand they need capital to adjust output to meet the demands of a diverse customer base. Although it is easy to keep the money flowing in a growing economy, it is not easy to do so in one that is slowing down or barely growing. When this happens, metal fabricators must cut costs and reduce variables to stay profitable.

By keeping an eye on competitor costs as well as streamlining their processes, players in the metal fabrication industry can protect their investments from external negative influences.

To lead the industry, therefore, metal fabricators must be able to streamline their processes and machinery, keep an eye on competitor costs and trends that affect their customers, and learn to identify economic trends so they can scale up or down as may be required.

The metal fabrication industry is a complicated one, but if there is one takeaway, it is that innovation, customer acquisition, and retention, as well as service diversification, are important if a metal fabrication shop wants to lead the industry.