Today, supply chain management (SCM) has become a crucial factor in achieving the success or failure of a company. Well-managed supply chains can significantly impact your company’s bottom line, customer satisfaction, and overall reputation.

But, managing the supply chains can be daunting, especially with the increasing complexities of global markets and the rising demand for faster delivery times. That’s why streamlining your supply chain management process is essential to ensure optimal efficiency.

This article will discuss the key steps you can take to streamline your supply chain management operations. These steps can improve your supply chain’s efficiency, reduce costs, and, after all, enhance customer satisfaction. So, let’s dive in and learn how to streamline your supply chain management.

📖 Short Summary

Streamlining your supply chain management is essential to ensure optimal efficiency and improve customer satisfaction.

Doing so can reduce costs, boost your business’s bottom line, and increase your client’s satisfaction.

It involves evaluating and optimizing existing processes, identifying areas of improvement, and leveraging technology for maximum efficiency.

What is supply chain management (SCM)?

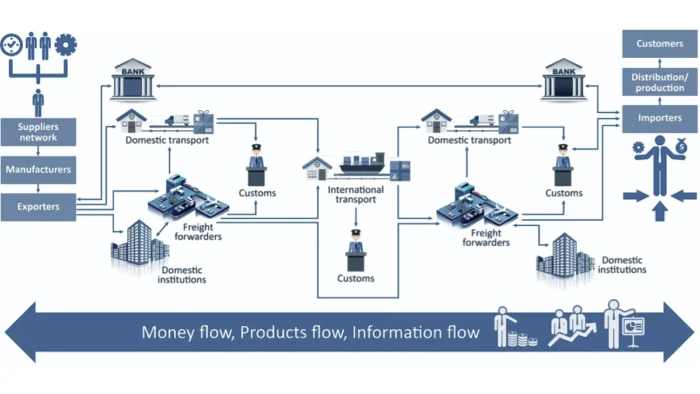

Managing the flow of materials and information from suppliers and buyers to the final customer is the essence of supply chain management.

A supply chain is a network of organizations (including governmental organizations) through which materials move from raw materials until the finished product arrives at the customers. I have intentionally included “governmental organizations” inside brackets because I want to emphasize the importance of these organizations in all supply chains. Based on countries where the goods will need to transit, the impact of regulations in those countries will affect supply chains.

The primary objective of supply chain management is to reduce overall costs and improve quality and service delivery by fostering cooperation among all entities inside the supply chains. Effective management requires a team approach, with functions such as marketing, purchasing, operations, and engineering collaborating closely.

Delivering a finished product or service to the customer involves a network of activities known as supply chain networks. These activities encompass everything from sourcing raw materials and parts to the manufacturing process and assembling the final product, warehousing, order entry and tracking, distribution through various channels, and delivery to the customer. To facilitate this process, companies rely on an information system that enables exchanging relevant information among chain members, such as sales data, sales forecasts, and promotions.

So, supply chain management (SCM) coordinates and manages all activities involved in producing and delivering a product or service. It aims to optimize the flow of goods and services, reduce costs, improve quality, and maximize the satisfaction of customers.

Effective supply chain management requires collaboration between stakeholders, suppliers, manufacturers, distributors, and retailers. It involves managing relationships with these stakeholders to ensure that the right products are delivered at the right time and cost.

The supply chain begins with external suppliers who provide and transport raw materials and components to the manufacturers. The manufacturers then transform these materials into the finished product and ship them to distribution centers or wholesalers. The product then moves on to retailers who sell it to the end customer.

Throughout this process, relevant information flows back and forth among supply chain members, ensuring a smooth and efficient operation.

Why is supply chain management important?

Logistics play an important role in the economy in two main ways:

- Logistics is the main cost in businesses, and because of that, it impacts on and is impacted by other economic activities of the private sector.

- Logistics support many transactions, from raw materials to end-user products.

In such complex supply chain networks, variations in delivery time and costs can greatly impact the performance of the last organizations inside the chain. Every trading company in the supply chain network depends on the services and products of another company. Therefore, the variability in time and costs can produce variability of orders, and variability of orders affects the appearance of the Forrester effect (also called the bullwhip effect), where orders sent to the first organization in the chain on the supply side has a much larger variance than the changes in orders at the last organization or end customer.

So, why is supply chain management important?

Supply chain management is important because it impacts a company’s bottom line, consumer satisfaction, and overall reputation. Well-managed supply chains can help companies reduce costs, improve quality, and ensure satisfaction. It can also help a company improve its competitive advantage by providing faster delivery times, better product availability, and lower prices.

On the other hand, a poorly managed supply chain can result in higher costs, longer lead times, and lower consumer satisfaction. It can also lead to negative publicity and damage a company’s reputation.

Common challenges in supply chain management (SCM)

Managing a supply chain is difficult, and companies face several challenges. Some of the common challenges include:

- Supply chain sustainability and green operations. There is a growing emphasis on sustainability, which involves reducing waste, recycling, and reusing products and raw materials. As a result, companies face increasing pressure from society to prioritize air and water quality, waste disposal, global warming, and other environmental concerns. The significance of this issue is highlighted by a series of standards known as ISO 14000, developed by the International Organization for Standardization (ISO). These standards offer guidelines and a certification program documenting a company’s environmentally responsible actions.

Organizations can introduce green requirements for suppliers to make supply chains eco-friendly, such as reducing carbon emissions and using sustainable farming. Compliance is monitored, and corrective action is taken if necessary. It’s also important to understand packaging restrictions and regulations. Companies should focus on sustainable product design and final disposition. Carbon footprint analysis is an effective approach to reducing the overall carbon footprint.

- Lack of visibility. Many supply chain managers struggle with visibility into their supply chain. They may not have real-time data on inventory levels, production schedules, or delivery times. This lack of visibility can lead to inefficiencies, delays, and higher costs.

- Complexities of global markets. With the rise of global markets, supply chain managers also face new challenges in managing their supply network. They must deal with different regulations, customs, and languages, as well as longer lead times and higher transportation costs.

- Increasing demand for faster delivery times. Customers increasingly demand faster delivery times, which pressures companies to optimize their supply chain. This can be difficult, especially for companies with complex global supply chains or remote locations.

- Inventory management. Managing inventory levels is another challenge for supply chain managers. Companies must balance the need for adequate inventory levels with the cost of carrying excess inventory.

Components of a Supply Chain

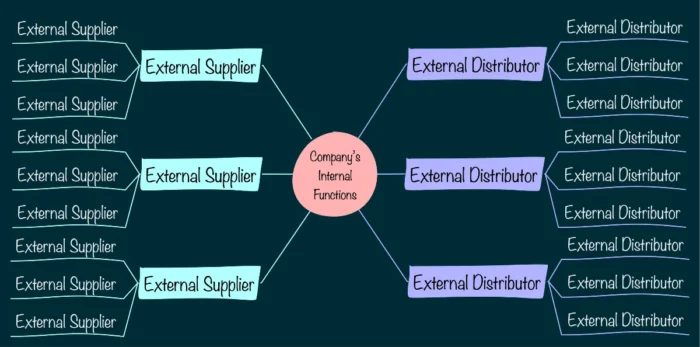

A supply chain has three components:

External Suppliers

In most cases, the manufacturing process involves multiple companies, with tier-one suppliers providing packaging materials directly to the processing facility. Tier-two suppliers provide materials to tier-one suppliers, while tier-three suppliers provide raw materials to tier-two suppliers. Supply chains vary in shape and size, with each customer being a supplier to another part of the chain, from raw materials until the final product reaches the final user.

Internal Functions

When we talk about internal functions, they are performed to ensure efficiency and quality. These functions include processing, converting raw materials into higher-level and finished products, and packaging them for wholesale and retail distribution.

External Distributors

External distributors transport finished products to the appropriate locations for eventual customer sales. The supply chain manager is responsible for managing the movement of products between locations. It includes:

- Traffic management is the selection and monitoring of external carriers (trucking companies, airlines, railroads, shipping companies, and couriers) or internal fleets of carriers.

- Distribution management is the packaging, storing, and handling of products (from raw materials to finished products) at receiving docks, warehouses, and retail outlets.

Streamlining your supply chain management process

To streamline your supply chain management process, you need to identify areas of inefficiency and take steps to improve them. Here are some key steps you can take:

Optimize inventory levels

Optimizing inventory levels is one of the most important steps in streamlining your supply chain management. This involves balancing the need for adequate inventory levels with the cost of carrying excess inventory. By optimizing inventory levels, you can reduce costs and improve efficiency.

You need real-time data on inventory levels, production schedules, and delivery times to optimize inventory levels. Also, you can use inventory management software to help you track inventory levels and make informed decisions about when to order more stock.

Improve communication with suppliers

Effective communication with suppliers is essential for a well-managed supply chain. You need to work closely with your suppliers to ensure that they understand your requirements and can deliver the right products at the right time.

To improve communication with suppliers, you can use tools such as supplier portals, which allow you to share information with your suppliers in real-time. You can also establish regular communication channels, such as weekly or monthly meetings, to discuss any issues or concerns.

Use automation

Automation can help you streamline your supply chain management operations by reducing manual tasks and improving efficiency. You can use automation tools such as robotics, artificial intelligence, and machine learning to automate inventory management, order processing, and transportation tasks.

Implement a supply chain management system

A supply chain management system can help you manage your supply chain more effectively. A supply chain management system can provide real-time data on inventory levels, production schedules, and delivery times, allowing you to make informed decisions about your supply chain.

Steps to optimize your supply chain management process

You need to take a systematic approach to optimize your supply chain management process. Here are some key steps you can take:

Analyze your supply chain

The first step in optimizing your supply chain management operations is to analyze your supply chain. You need to identify areas of inefficiency and determine the root cause of any problems and low supply chain performance. This may involve conducting a supply chain audit or using tools such as value stream mapping to identify waste areas. To analyze your supply chain, you can start with the following steps:

- Identify all supply chain managers inside the network. Inform them that you, as a supply chain manager, want to improve supply chain performance; because of that, you expect collaboration with all of them.

- Gather data from all supply chain managers.

- Analyze the data and identify areas of inefficiency. Remember that when you analyze the data, you want to identify any issues or bottlenecks in the supply chain.

Set goals and metrics.

Once you have identified areas of inefficiency, you need to set goals and metrics to measure your progress. You may want to set goals such as reducing lead times, improving on-time delivery rates, or reducing inventory levels.

Develop a process improvement plan for effective supply chain management

Now it is time for supply chain planning. You must develop a plan to optimize your supply chain management operations based on your analysis and goals. This may involve implementing new technologies, improving supplier communication, or reorganizing your supply chain.

Implement your plan

Once you have developed a plan, you need to implement it. This may involve training employees, implementing new technologies, or changing your processes.

Monitor and evaluate

Finally, you must monitor and evaluate your supply chain performance to ensure it works effectively and review the effectiveness of your process improvement plan. You can use your Key Performance Indicators (KPIs) to measure your progress and identify areas for improvement.

Here are the seven most important supply chain KPIs to monitor the performance of your supply chain:

- Cost of Goods Sold (COGS),

- Inventory Turnover Ratio,

- Order Fulfilment Rate,

- On-Time Delivery Rate,

- Economic Order Quantity,

- Lead Time,

- Return on Investment (ROI) for your supply chain activities.

This will help you identify areas where further improvements can be made and ensure that your supply chain management is as efficient as possible.

Technologies that can improve supply chain management

Several technologies can help you improve your supply chain management process. Here are some examples:

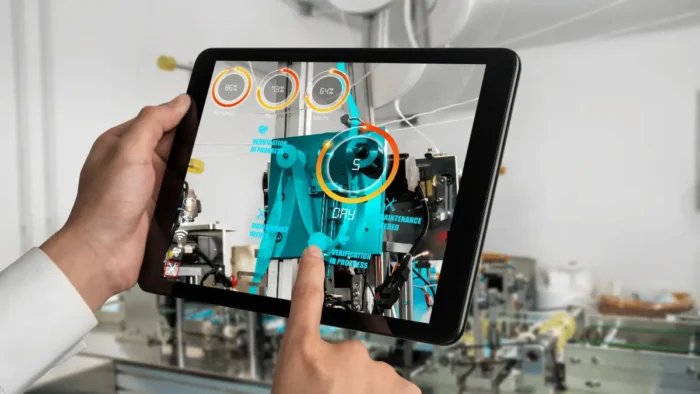

Augmented Reality (AR) and Virtual Reality (VR)

AR and VR have the potential to revolutionize supply chain management by providing real-time data on inventory levels, product tracking, and delivery times. For example, AR can give workers a virtual view of a warehouse or manufacturing process to reduce errors and improve accuracy. On the other side, VR can help simulate the entire supply chain, allowing you to test different scenarios and make better decisions.

Artificial Intelligence (AI) & Big Data

AI technologies such as Machine Learning (ML) and Natural Language Processing (NLP) can automate many supply chain management processes. AI-based tools can predict demand, optimize fulfillment routes, and streamline supplier communication. For example, by using AI in the supply chains, you can automate order processing and optimize delivery routes in real-time.

On the other side, big data is a powerful way to analyze large quantities of data from various sources and optimize the performance of your supply chain. By using big data, you can gain insights into customer demand, predict disruptions, and optimize inventory levels in real-time. This helps to reduce costs and ensure efficient operations throughout the supply chain.

Blockchain

Blockchain technology can help to increase trust and transparency in the supply chain by providing an accurate, secure, and immutable record of transactions. This will allow you to track goods from production to delivery, reducing errors and improving accuracy.

Cloud Computing

Cloud computing can help you manage supply chain data more efficiently by reducing the cost of storing and managing large amounts of data. This technology can also be used to develop connected supply chains, allowing for better collaboration between supply chain partners. This leads to better visibility across the supply chains and more efficient operations.

Internet of Things (IoT)

The IoT is a connected device network that collects and analyzes real-time data. You can gain better visibility and control over your supply chain operations using the IoT. This will help you make smarter decisions and optimize your processes for maximum efficiency.

Robotics Process Automation (RPA)

RPA is a form of automation that can automate manual and repetitive tasks in the supply chain. This can reduce costs, increase productivity, and improve customer service. For example, RPA in warehousing and manufacturing can help you automate repetitive tasks to improve the speed of operations and reduce error rates.

Radio Frequency Identification (RFID)

RFID is a technology that allows you to track inventory in real time. It involves attaching a small tag to each product, which can be scanned using a handheld device. RFID can help you improve inventory accuracy, reduce stockouts, and enhance supply chain visibility.

Autonomous vehicles

Autonomous vehicles like self-driving trucks and drones can deliver goods faster and more efficiently. This will help you reduce delivery times and operational costs and improve customer experience.

Electronic Data Interchange (EDI)

EDI technology allows you to exchange business documents with your suppliers electronically. It can help you improve supplier communication, reduce lead times, and enhance supply chain visibility.

Transportation Management Systems (TMS)

TMS is a software system that allows you to manage your transportation operations more effectively. It can help you optimize delivery routes, reduce transportation costs, and improve on-time delivery rates.

Benefits of an efficient supply chain management operations

Efficient supply chain management is important because it can provide several benefits for your business, including:

Reduced costs

Streamlining your supply chains can reduce inventory, transportation, and labor costs.

Improved quality

By optimizing your supply chain management process, you can improve the quality of your products and services, which can lead to higher consumer satisfaction.

Improved consumer satisfaction

An effective supply chain management process can help you provide faster delivery times, better product availability, and lower prices, enhancing consumer satisfaction.

Improved competitive advantage

By streamlining your supply chain management process, you can improve your competitive advantage by providing faster delivery times, better product availability, and lower prices.

Case studies of successful supply chain management

Several examples of companies have successfully streamlined their supply chain management process. Here are some examples:

Walmart

Walmart is known for its effective supply chain management. The company uses a sophisticated logistics system to manage its supply chain, which involves real-time data on inventory levels, production schedules, and delivery times.

Walmart has long been a leader in the retail industry, and its supply chain is no exception. The company significantly invested in technology and automation to improve its supply chain operations. Their supply chain strategy focuses on direct, long-term relationships with different supply chain members like manufacturers, distributors, and e-commerce businesses. This practice, known as cross-docking, minimizes inventory carrying costs and the duration of the Walmart product’s transport from the factory to the customer.

The innovative approach to Walmart’s supply chain management has been a key driver of its success. From its early adoption of barcode scanning technology to its current use of data analytics and automated systems, Walmart has consistently sought ways to increase efficiency in its supply chain operations. Walmart is making massive investments to improve its supply chain further. The retailer reported in 2021 that in the previous two years, the company had invested more than $11 billion in this area in a new, more connected, and automated supply chain, which improved the experience for its customers and increased the productivity of all partners inside their supply chain networks.

Through automation and emerging technology, Walmart is building a scaled system of supply chain capabilities that uses data, software, and robotics. This increased item storage allows the distribution center to provide a more consistent, predictable, and higher-quality delivery service to stores and customers while allowing them to react more quickly to customer demand.

Zara’s Successful Supply Chain Management

Zara, one of the world’s largest fashion retailers, has achieved success through its unique supply chain management. By leveraging technology and automation, Zara has remained relevant in a highly competitive market and provided customers with a “fast fashion business model” at an affordable price. This business model involves producing small batches of clothing and quickly replenishing inventory based on customer demand.

The organization’s supply chain is based on a lean and agile model. Stores take deliveries twice per week, and they can get ordered inventory often within two days after ordering. Additionally, Zara handles all distribution from Spanish warehouses – all goods are shipped to Spain by manufacturers and distributed across the globe. This helps reduce costs while still providing customers with timely delivery of products.

Zara has implemented different strategies to manage its supply chain to remain competitive. These include rapid-fire fulfillment, which enables quick response times, quick response to demand, and regional networks for efficient distribution of goods across multiple countries. All these strategies have enabled Zara to stay ahead of its competitors regarding speed-to-market and cost control.

Technology also plays a major role in managing the supply chain at Zara. Automation has allowed them to improve their processes to produce more products faster while decreasing costs. Additionally, artificial intelligence (AI) is used to analyze customer data so that designers can create new products based on current trends and customer preferences more quickly than ever. Machine learning algorithms are also used for demand planning to adjust production accordingly without overstocking or understocking any items in their stores or warehouses.

Overall, Zara’s innovative approach to managing its supply chain has allowed the company to remain successful in a highly competitive market by providing customers with fast fashion at an affordable price while maintaining high-quality standards throughout its operations. By leveraging technology such as automation, AI, and machine learning algorithms, they have improved speed-to-market and cost control while staying ahead of their competitors regarding product design and delivery times.

Amazon Supply Chain Management

Amazon is one of the largest e-commerce retailers in the world, and its success can be attributed to its innovative supply chain management. The company has developed a unique supply chain strategy to remain competitive.

Amazon uses a mixed supply chain strategy that allows them to reduce delivery time while also controlling costs. The term “Amazon supply chain” covers everything from storage and inventory to pricing and shipping. Amazon has implemented various strategies such as automation, artificial intelligence (AI), machine learning (ML), and cloud computing to optimize its supply chain for speed-to-market and cost control.

Despite the company’s success in managing the supply chains, Amazon still faces challenges when managing its operations. One of these challenges is ensuring that products are delivered on time and within the budget. To address this challenge, Amazon has implemented various strategies, such as using predictive analytics to anticipate customer demand and implementing automated systems for tracking inventory levels. Additionally, they have implemented strict quality control measures throughout their supply chain process to ensure customers receive high-quality products on time.

Amazon’s successful supply chain management is largely due to its innovative use of automation, AI, ML, and cloud computing technology.

Common mistakes in supply chain management

There are several common mistakes that companies make in supply chain management. Here are some examples:

Not investing in technology.

Technology can help companies to optimize their supply chain processes, but many businesses neglect to invest in new technologies.

Lack of communication

Effective communication is essential for a well-managed supply chain. Companies that fail to communicate effectively with their suppliers and customers will likely experience inefficiencies and delays.

Over-reliance on a single supplier

Relying too heavily on a single supplier can be risky, leaving you vulnerable to disruptions in the supply chain. Companies should consider diversifying their supplier base to minimize risk.

Failure to adapt to changing market conditions

Companies that fail to adapt to changing market conditions will likely experience inefficiencies and lost opportunities. It’s important to stay up-to-date with industry trends and adjust your supply chain management processes accordingly.

Conclusion

In conclusion, supply chain management is a crucial factor in determining the success or failure of a company. Streamlining your supply chain management operations can improve efficiency, reduce costs, and increase the satisfaction of customers. However, managing a supply chain is difficult, and companies face many challenges. By systematically using technology, you can optimize your supply chain management system and provide value to your customers. It’s also important to remember that supply chain management is an ongoing process that requires continuous evaluation and improvement. By staying up-to-date with industry trends and adjusting your business processes accordingly, you can stay ahead of the competition and provide value to your customers.

Frequently Asked Questions

Supply chain management is the process of coordinating and managing different activities related to producing and delivering a product or service, from raw materials to finished products. The ultimate goal of SCM is to ensure a seamless flow of goods, minimize costs, ensure high-quality products, and provide great buyer satisfaction.

Managing the supply chain is important for companies because it affects their financial performance, consumer satisfaction, and overall reputation. Streamlining the supply chain can result in cost savings, higher-quality products, and increased customer satisfaction. It can also bring a competitive advantage through quick delivery, better product availability, and lower prices.

Common mistakes in supply chain management include not investing in technology, lack of communication with suppliers/customers, over-reliance on a single supplier, and failure to adapt to changing market conditions.

You can optimize your supply chain management system by investing in new technologies such as automation or AI; communicating effectively with your suppliers and customers; diversifying your supplier base; staying up-to-date with industry trends; and adjusting processes accordingly.