There are several ways in which plastic parts can be manufactured. Two of the predominant ones include vacuum molding & injection molding. Both processes involve benefits contingent on the specific application. Vacuum molding, also called thermoforming, is generally utilized for large-scale designs with quicker production runs, whereas injection molding is more suitable for making small intricate parts with substantial production runs.

What Does Vacuum Molding Entail?

One of the most cost-effective thermoforming vacuum forming technologies. In order to vacuum mold a plastic item:

- A leaf of thermoplastic material gets heated in an oven.

- The heated sheet is then set on a mold.

- Air is then pulled out of the mold via a vacuum, tugging the sheet against the mold to form the shape.

- After the formed plastic has cooled down and hardened, it is removed from the mold and gets trimmed.

Benefits Of Vacuum Molding

- The shorter time during production.

- Design flexibility.

- Cheaper tooling costs in comparison to injection molding.

- Prototypes can be made accurately and quickly. Check https://prototechasia.com/en/how-does-the-vacuum-molding-process-work work for more information.

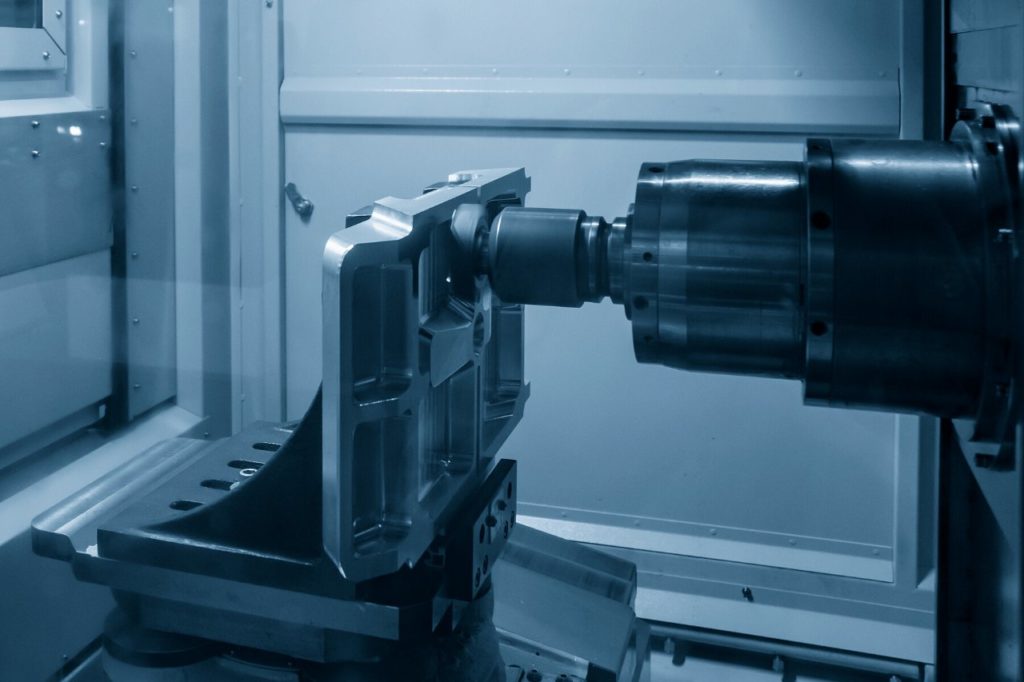

What Does Injection Molding Entail?

Injection molding is one of the most regular plastic forming processes. To injection mold a plastic item:

- Hot melted plastic gets injected under significant pressure between the mold cavity and the core.

- After the plastic has cooled down enough and solidified, the mold cavity is opened, and the part ejected.

Benefits Of Injection Molding

- Automated process to save manufacturing expenses.

- It is an efficient material use with little post-production waste.

- It is precise, effective processing for substantial volumes of small parts.

- Involves highly engineered and detailed tooling with multi-cavity mold choices.

Vacuum Molding Versus Injection Molding

What really makes a difference when deciding on a molding process is the secondary operations and finishing required. Vacuum molding of plastic parts is not as problem-free as injection molding. There are certain secondary operations that are necessitated to make the elements get the desired look. While the vacuum molding process is somewhat more comprehensive, the tooling is more cost-effective, the production time is quicker, and the aesthetics obtained are moderately the same.

For most people, injection molding may not make sense until they are involved with high-volume production. Injection molding tooling takes a significant amount of time to produce (it can take anywhere from twelve to sixteen weeks), where vacuum molding tooling only takes about six to eight weeks. However, your per-piece production fees on vacuum molded parts are more significant as opposed to injection molded parts.

Nowadays, mindsets in business have changed to be more about how fast something can be obtained. People often don’t like to purchase a lot of things that they don’t necessitate right away. People would instead deliberate that they will get whatever they need and not more. In manufacturing, the question most people struggle with is, “How can I get my product to quickly market, and how will it be possible only to buy what I necessitate? With injection molding, it’s not easy to do just that. However, with vacuum molding, it can be quickly done.