If you’re unfamiliar with thermal spray coating, you might wonder what it is and how it can benefit your business.

Thermal spray coating is a process that applies a protective or decorative coating to a surface using heat and pressure. The resulting coatings are incredibly durable and can improve the function or aesthetics of the coated item. This blog post will discuss everything you need to know about this coating, including its advantages, applications, and more.

Whether you’re considering thermal spray coating for your business or want to learn more about it, read on for all the details.

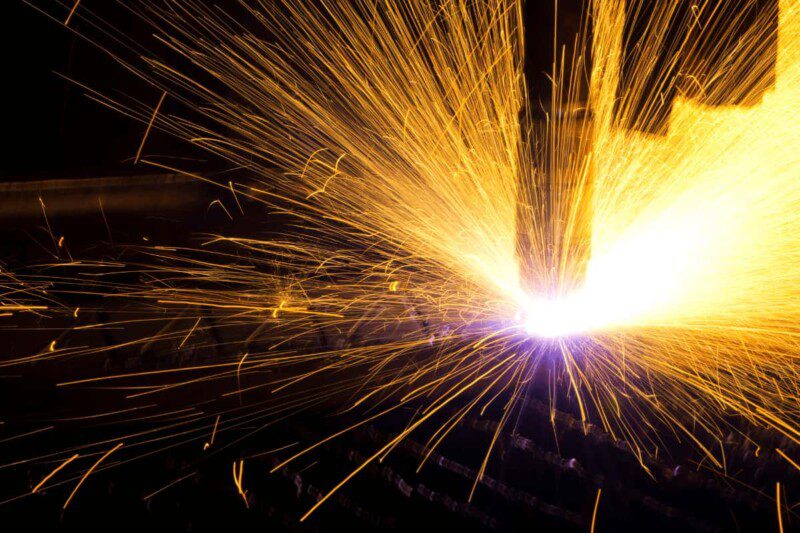

How does it work?

Thermal spray coating is a highly effective process for corrosion, wear, and erosion protection to various materials. The process works by using a thermal spray gun to melt specially formulated alloys, which are then propelled toward the substrate at high speed. As the particles hit, they instantly cool and solidify, forming the protective coating. This can protect the substrate against harsh environmental conditions and improve its surface properties in terms of toughness and durability.

This coating also provides excellent electrical insulation and abrasive resistance, making them a cost-effective alternative to other coating methods such as galvanizing or plating.

The benefits:

Thermal spray coatings offer homeowners and business owners a range of benefits that can help protect their surfaces effectively. Whether it is a roof, walls, pipes, or other surfaces around the home or place of work, this coating acts as a tight barrier to heat and moisture. Twin wire arc spray is just one type of this coating that offers maximum protection in various settings. The twin-wire process produces firm coatings, which can be more durable and resistant to abrasion when compared with single-wire arc processes.

Additionally, twin wire arc spray also preserves the original properties of the substrate material for better thermal insulation. This method keeps surfaces safe from water damage and reduces airflow significantly to improve energy efficiency.

Choosing the suitable thermal spray coating

Thermal spray coating is a practical application for a variety of requirements. However, it is essential to determine the correct type of coating for the job. Many factors should be considered when choosing the most suitable coating option. Surface properties such as roughness, bond strength, and compatibility; desired performance, wear resistance, and erosion characteristics; the environment in which the part will operate; and cost constraints all need to be accounted for before making a decision. Working directly with a thermal-spray specialist can help you select the ideal coating that is both cost-effective and provides maximum protection.

With their assistance, you can confidently choose the suitable thermal spray coating for your project’s specific needs.

Types of thermal spray coatings available

Thermal spray coatings provide many advantages for different materials, ranging from corrosion and wear protection lubrication to insulation and even aesthetic enhancements. These coatings are created by heating a feedstock material with an energy source before accelerating it toward the coated object.

Popular types of thermal spray coatings include plasma spray coatings, high-velocity oxy-fuel (HVOF), and detonation gun coating. Each type has its particularities regarding applicability in specific situations and its desired effects.

Plasma spray coatings produce high temperatures for use on thicker objects. HVOF can work with a wide variety of feedstock materials, including alloys of metals like stainless steel, cobalt-chrome alloy, nickel-chrome alloys, aluminum oxide, and titanium carbide, as well as plastics like polyethylene, PEEK, or nylon 6/6.

Detonation gun systems excel at applying ceramic layers while avoiding oxygen contamination – making them ideal for components that require hardness or wear resistance, such as rolling bearings or power transmission components. When it comes to achieving the proper performance for your application needs, you can rely on different choices of thermal spray coatings to help you get there!

The best way to apply a thermal spray coating

Applying this coating is an efficient way to achieve the desired application requirements. The process involves heating a material, typically a metal or plastic, into a molten or semi-molten state. This heated material is then sprayed onto the surface, creating a layer of coating that provides protection and improves the material’s overall performance.

For optimal results, it’s essential to select an appropriate and high-quality material, properly prepare the substrate surface, control spraying parameters like velocity and distance accurately, and carefully inspect the work after completion. Utilizing highly-trained personnel; modern, precise equipment; and reliable processes will help ensure that each job is done right.

Thermal spray coating can enhance properties such as wear resistance, corrosion resistance, and lubricity for virtually any metal or alloy substrates – making it one of the most versatile coatings available.

Tips for maintaining thermal spray coating over time

Keeping your thermal spray coating in top condition over time requires adequate preparation and maintenance. It is crucial to thoroughly clean the equipment and the surfaces you are planning to coat before beginning the process.

Be sure to check for burrs, pits, and other surface irregularities before spraying – these can affect adhesion and decrease the life of your coating. Regularly inspect the substrate for signs of corrosion or cracking, mainly if it is a component exposed to exterior elements, as this can lead to premature failure of the coating. Lastly, use approved lubricants when appropriate, as they can reduce wear on metallic and non-metallic parts and prevent damage caused by abrasion. Following these tips will ensure that your thermal spray coating lasts as long as possible.

Concluding thoughts

In conclusion, thermal spray coating is a great way to protect surfaces from the elements, both inside and outside the home or business. Its unique ability to create strong protective coatings can be used for various materials such as metal, wood, plastic, and more. Not only does this coating protect surfaces from damage caused by environmental factors, but it also enhances their durability, temperature resistance, and even aesthetics.

When choosing a thermal spray coating for your home or business needs, it’s essential to consider material type, application method, and maintenance considerations to make sure you find the right one for yourself.

Finally, when applying thermal spray coating, be sure to follow manufacturer recommendations closely to ensure optimal results and longevity of your surface protection. With these tips in mind, you’ll be well on your way to having a safe and lasting surface, whichever coating you choose!