Selecting the right filler suppliers is crucial for ensuring the quality and safety of your products. Whether you’re in the food, pharmaceutical, or cosmetic industry, the choice of fillers plays a vital role in the success of your business.

Here are the essential criteria you should consider when evaluating filler suppliers. By the end, you’ll be equipped with the knowledge required to make informed decisions that protect your product integrity and your brand reputation.

Product Quality and Compliance

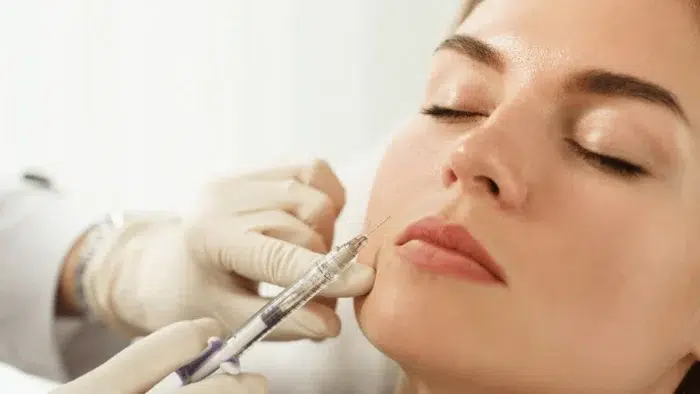

When assessing potential filler suppliers, prioritize those who adhere to strict quality standards. Confirm that their products comply with relevant industry regulations and certifications. Suppose you’re in the cosmetics industry and provide lip or face fillers for your clients. In that case, authentic Juvederm fillers offer a trusted and proven solution for achieving natural-looking and long-lasting results in various cosmetic procedures.

This commitment to quality ensures that the fillers you receive meet or exceed the necessary standards, preventing potential issues down the production line.

Supply Chain Transparency

Understanding the origin and journey of your fillers is vital. Opt for suppliers who prioritize transparency in their supply chain. A clear and traceable supply chain not only minimizes the risk of contamination but also helps you build trust with your consumers, who increasingly demand transparency in sourcing raw materials.

Consistency and Reliability

Consistency is critical in manufacturing. Your chosen filler supplier should demonstrate a track record of providing consistent products. Reliability in terms of on-time deliveries and a stable supply is equally important. This ensures your production processes remain uninterrupted, meet deadlines, and satisfy your customers.

Here is what you can do to ensure consistency and reliability:

- Production process stability. Choose a well-established and stable supplier without variations or low levels of variations in the production process. This stability indicates their commitment to delivering consistent product quality, minimizing variations that could impact your end products.

- Quality control measures. Investigate the quality control measures implemented by the supplier. A reliable supplier conducts rigorous testing at various stages of production, ensuring that each batch of fillers meets specified standards. This dedication to quality control contributes to the reliability of their products.

- On-time deliveries. Timely deliveries are crucial to maintaining an efficient production schedule. Assess the supplier’s track record for on-time deliveries and inquire about their logistics and distribution capabilities. A supplier who consistently meets deadlines helps avoid production delays and potential financial losses.

- Supply chain resilience. Consider the resilience of the supplier’s supply chain. A robust and adaptable supply chain is better equipped to handle unexpected challenges like raw material shortages or transportation disruptions.

Technical Support and Expertise

Look for suppliers who offer more than just products. A reliable filler supplier should provide technical support and expertise. This can be valuable in troubleshooting issues, optimizing processes, and even exploring innovative applications for their fillers within your product range.

Customization Options

Every product is unique, and your filler supplier should recognize that. Opt for a supplier that offers customization options to meet your specific requirements. This flexibility lets you fine-tune your formulations and stay ahead of market trends.

Formulation Flexibility

You must ensure that your chosen filler suppliers offers a range of formulations to accommodate diverse product needs. This formulation flexibility allows you to adapt your formulations in the right way to meet your end product’s specific requirements.

Particle Size and Shape Variability

Opt for a supplier that provides options for varying particle sizes and shapes. This level of customization can influence the texture, appearance, and performance of your final product. Tailoring these characteristics to your exact specifications improves the uniqueness of your offerings.

Color and Visual Appeal

Customizing the color of fillers is essential, especially in industries where visual appeal plays a crucial role. A supplier offering a high range of color options allows you to align your products with brand identity or market trends, creating a distinct visual presence in the market.

Specialized Additives and Features

Consider suppliers who can incorporate specialized additives or features into their fillers. Whether fortifying your product with specific nutrients, enhancing shelf life, or achieving a particular texture, a supplier with a repertoire of additives broadens your customization possibilities.

Cost-Effectiveness

While quality is essential, cost-effectiveness is also a significant consideration you must make. Evaluate the overall value that a filler supplier brings to your business. You can use value chain analysis to do this.

Consider factors such as bulk pricing, discounts for long-term partnerships, and any additional services or perks they may offer.

Conclusion

Choosing a filler supplier involves a careful consideration of multiple factors. Prioritize quality, transparency, and reliability to ensure your products meet the highest standards. A supplier with a transparent supply chain, consistent product quality, and the ability to offer technical support can become a valuable partner in your business success.

Make sure to consider customization options and cost-effectiveness, as these aspects contribute to the overall value a supplier brings to your operation.